Corrosion-resistant magnetic pump refers to fluoroplastic magnetic pump and stainless steel magnetic pump based on fluoroplastic and stainless steel. Let's talk about the selection guide of fluoroplastic magnetic pump first.

The flow passage part of the fluoroplastic magnetic pump is F46, and the remaining materials are the main shaft of silicon carbide, the static ring of the pump body, the rear port ring of the impeller, the sliding bearing; and the fluororubber sealing ring for sealing.

It is well known that F46 can withstand the corrosion of the medium, but the silicon carbide material has a tolerance range. Due to economic factors, the standard silicon carbide of the fluoroplastic magnetic pump is reactive sintered silicon carbide, and the purity is generally 93%~95% In between, the remaining 5% or so are mainly silica crystals. Silicon carbide is also very stable at room temperature, but silica will react with many media at room temperature, such as caustic soda, hydrofluoric acid, phosphate, and so on. The chemical reaction equation is as follows:

Reaction of caustic soda and silica: SiO2+2NaOH=Na2SiO3+H2O

Hydrofluoric acid and silica reaction: 6HF+SiO2=H2SiF6+2H2O

The above reaction will destroy the main structure of the silicon carbide, so that the surface roughness of the silicon carbide is improved, and it becomes a frosted state, which accelerates the wear rate of the abrasive parts. Therefore, the corrosiveness of the conveying medium must be studied when selecting materials, otherwise the service life of the corrosion-resistant magnetic pump will be shortened.

When transporting media such as nitric acid and organic solvents, fluorine rubber sealing rings should not be selected, and fluorine-containing sealing rings should be used, because fluorine rubber sealing rings will expand and lose elasticity in nitric acid and organic solvents, which will affect the sealing performance.

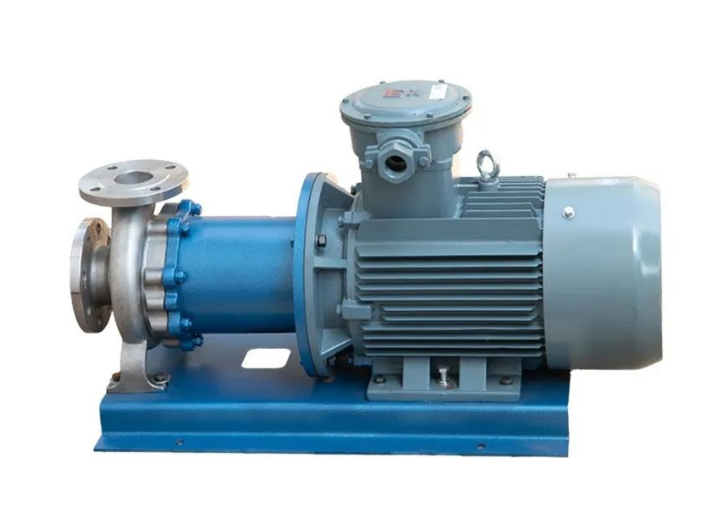

Then introduce the selection points of the stainless steel base magnetic pump in the corrosion-resistant magnetic pump.

Stainless steel magnetic pump is mainly based on austenitic stainless steel. Austenitic stainless steel magnetic pump has poor corrosion resistance in acidic medium, but has inert performance in lye corrosive medium. Therefore, the corrosion-resistant magnetic pump of stainless steel is generally selected in the solution containing alkaline medium.

Except that the wetted parts are austenitic stainless steel, the remaining materials immersed in the medium are: SIC, tungsten carbide tungsten carbide, austenitic stainless steel after ion nitriding; and all-tetrafluoro gaskets.

The reaction of silicon carbide in lye solution As mentioned above, cemented carbide tungsten carbide, ion nitrided stainless steel, etc. all show inertness in lye solution. Therefore, when transporting media such as caustic soda, the opposite abrasive parts of cemented carbide tungsten carbide are generally selected.